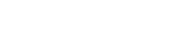

The SwissPress is a fully equipped, high-precision automatic punching press with servo drive. The turnkey production system consists of a punching press and control, as well as monitoring, feed, and lubrication systems.

Based on a cast iron press body, the press mechanics developed by Arcofil SA boast high rigidity and good vibration damping. The press design guarantees high-precision ram guidance, protecting sensitive elements in the tool and improving the press service life.

Thanks to the servo drive, it is possible to control the punching process via a travel profile if required. For a stamping operation, for example, the ram speed can be decreased and then increased again for the remaining stroke.

This can both improve the part quality and increase the output. Only tried-and-tested Siegfried products are used for the press control and all peripheral systems. A functional protective housing combines the press and all peripherals into a single compact, ergonomic production system. The SwissPress is delivered fully assembled, tested, and certified, and is ready for immediate use in just a few simple steps. The two partner companies developed the system with a focus on meeting the high requirements of the Swiss watch industry, exploiting their many years of experience as system suppliers in this sector. The SwissPress is developed, produced, and assembled exclusively in Switzerland.

Control system

The Siegfried Advanced Software SAS integrates the control and all peripherals into a single system. This ensures maximum user friendliness, efficiency, and flexibility. The control system can be supplemented and adapted with additional modules at any time as required. All parameters for the press, monitoring, feed, and oiling are configured on a standardized interface and stored in a shared data record.

Monitoring

Even the basic version of SwissPress features press force monitoring, 8 digital tool protection inputs, and 8 digital control outputs. The tried-and-tested modules and functions of the Siegfried Advanced Software SAS ensure the reliable monitoring of the entire system. This provides reliable protection against machine and tool damage and reduces incorrect punching operations. Downtimes are thereby kept to a minimum while increasing the output of the system.

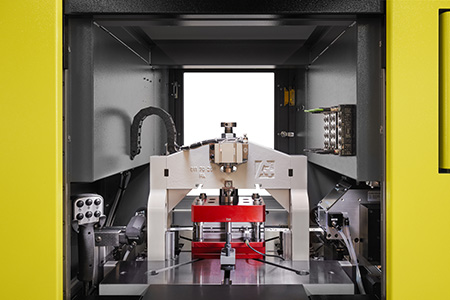

Feed system

The proven Siegfried CombiFeed is used as the feeder. This is driven by a servo motor. The backlash-free coupling of the two rollers ensures extremely high precision. The two pressure cylinders assure that the unit remains torsion-free and can help ventilate the press very rapidly by dividing the air volume. The most frequently used features and the enabling function for safe feeding can be conveniently operated using the manual control.

Oiling system

When lubricating the punching strip with Siegfried Advanced Lubrication SAL, it is possible to exactly dose oil in very small quantities and apply it with perfect reproducibility. If required, the system can be supplemented with additional modules for precise lubrication directly in the tool. All components required for operation, such as oil cans for fresh and residual oil, the spray chamber, and the LubeCubes with high-precision gear pumps, are integrated in the system’s protective housing.

Technical data

| Nominal force | 120 kN | ||

| Number of strokes | 0 – 500 1/min. | ||

| Drive | Direktantrieb, Servomotor | ||

| Fixed stroke | 20 mm | ||

| Maximum tool length | 305 mm | ||

| Daylight | 199 – 249 mm | ||

| Ram adjustment path | 50 mm | ||

| Maximum belt width | 45 mm | ||

| Outer dimensions with housing (W x T x H) | 1150 mm, 1240 mm, 1870 mm | ||

| Total weight | 2.6 t |