CUSTOMER BENEFITS

-

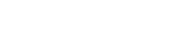

POWERFUL PERFORMANCE

Compact, high-performance feeder system with optional integrated stamp strip lubrication. -

IDEAL FUNCTIONING

Optimal stamp strip lubrication at all times. -

SAVING COSTS

By combining the feeder and lubrication systems, investment and operation costs are reduced. -

SIMPLE OPERATION

Clear and well-structured user interface.

PRODUCTS

-

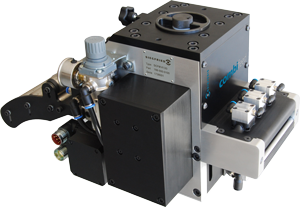

CombiFeed Base

Electronic roller feeder systems. -

CombiFeed

Electronic roller feeder systems with integrated strip lubrication.